News

Chain-Tail have offered more than 2000 customized models to markets with torque range 0.02 to 1000 Nm. Products can be provided per customer’s requests at competitive costs and economic batches.

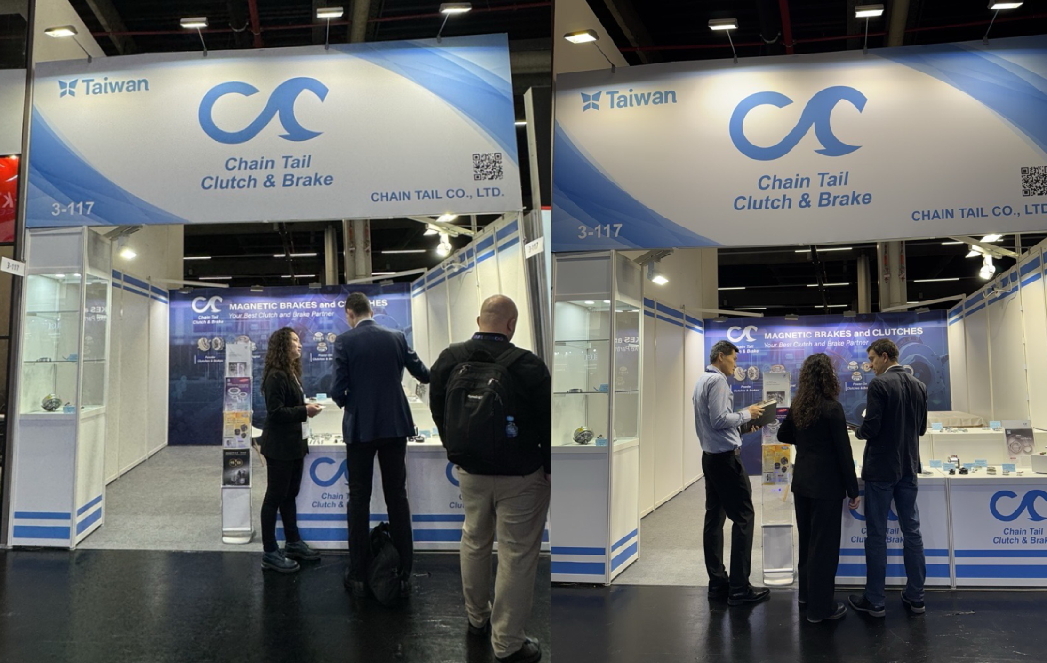

The 2025 SPS – Smart Production Solutions exhibition has successfully come to an end, marking another year of innovation, professional exchange, and industry advancement. This year’s show brought together a high-quality international audience and leading global exhibitors, all focused on the future of intelligent and digital automation.

SPS is recognized as one of the most influential exhibitions in the industrial automation sector, covering the full spectrum of automation technologies—from sensors to intelligent solutions and advanced digital industrial systems. Key themes of this year’s exhibition included:

-

Control Technology

-

Interface Technology

-

Electric Drive Systems & Motion Control

-

Human-Machine Interface Devices

-

Sensor Technology

-

Software & IT in Manufacturing

-

Mechanical Infrastructure

-

Industrial Communication

-

Industrial PCs (IPCs)

-

Drive Systems and Components

Throughout the exhibition, we showcased our latest technologies and solutions, engaging in valuable discussions with professionals and industry leaders from around the world. The show’s clear and targeted themes enabled efficient communication, providing excellent opportunities for business development and meaningful cooperation.

We extend our sincere appreciation to all customers, partners, and visitors who stopped by our booth. We will continue to strengthen our innovation capabilities and deliver smarter, more efficient automation solutions. We look forward to meeting you again at the next SPS exhibition.

We sincerely appreciate every team member for your dedication and hard work throughout the year.

Your efforts have allowed our company to move forward steadily in every project and every challenge we faced.

This Xiaoliuqiu employee trip is a small token of our gratitude.

We hope you can relax, enjoy the beautiful island scenery,

and strengthen connections with one another.

Recharge yourselves, and let us continue moving toward the future together.

Thank you for being an essential part of our team and contributing to our growth.

Wishing everyone a joyful and fulfilling trip!

Manufacturing World Japan 2025 – Tokyo Mechanical Components & Materials Expo – has successfully come to a close. As one of the world’s leading professional exhibitions for mechanical components, custom machining, and subcontracting services, the event gathered experts from across the globe to exchange the latest innovations and manufacturing trends.

As Japan’s largest and most comprehensive trade show for mechanical parts—including bearings, fasteners, springs, metal and plastic processing technologies—the exhibition remains a key platform for Asia’s advanced manufacturing industry. During the show, we received valuable business opportunities and established multiple potential collaborations, highlighting the strong demand in the Japanese market for high-quality machining solutions.

We sincerely thank all visitors, partners, and friends who stopped by our booth. We will continue to enhance our capabilities and expand our presence in Japan and worldwide. We look forward to meeting you again at the next exhibition.

South China International Industry Fair 2025, held from June 4th to 6th at Shenzhen World Exhibition & Convention Center.

Chain Tail displays variety of clutches and brakes which assist in upgrade the performance and optimize efficiency of automation equipment. We extend our gratitude to everyone who visited our booth, receiving universal praise and making SCIIF 2025’s participation a great success.

To align with global standards and fulfill our commitment to environmental sustainability, Chain Tail is dedicated to utilizing raw materials that comply with conflict-free mineral standards in production, ensuring product performance and reliability remain unaffected.

Energy conservation and equipment efficiency improvements are promoted across all our factory sites to reduce energy consumption. Regarding product packaging, in addition to providing customers with product safety assurance, we prioritize green design principles such as material reduction, recycling, reuse, and regeneration. We also emphasize on minimizing packaging volume and optimizing logistics to reduce resource use.

Environmental, Health, and Safety (EHS) Policy

1. Conserve Earth's resources and reduce product environmental impact to achieve a hazardous substance-free goal.

2. Through ongoing efforts in resource recycling and reuse for a lower environmental impact.

3. Enhance employee training and supplier awareness to strengthen environmental and safety practices.

4. Proactively inspect and eliminate unsafe behaviors and environmental hazards to prevent accidents.

5. Achieving full employee engagement to build a safe and healthy workplace.

The SPS from 25 – 27 November 2025 in Nuremberg is the industry highlight of the automation sector and, with its large number of exhibitors and unique concept, represents the complete spectrum of smart and digital automation – from simple sensors to intelligent solutions, from what is feasible today to the vision of a comprehensively digitized industrial world.

CHAIN TAIL HALL 3, STAND 117 , Welcome to visit us !

[ Taiwan Automation Intelligence and Robot Show ]

Venue: Taipei Nangang International Exhibition Center, Hall 2

Address: No. 2, Jingmao 2nd Rd., Nangang District, Taipei City 11568, Taiwan

Automation has developed rapidly and widely range of application recently.

It has become an indispensable valuable addition of industrialization.

This year CT will be attending this show at Hall 2 , No. P1327 , Welcome to visit us!

Mechanical Components & Materials Technology Expo [M-Tech] is an exhibition gathering all kinds of mechanical parts such as bearings, fasteners, mechanical springs, metal and plastic processing technology. M-Tech attracts a significant number of professionals every year from design, development, manufacturing, production engineering, purchasing and quality control departments, to conduct lively business discussions with exhibitors.

This year CT will be attending this show, at HALL 5 ,No. 30-24 ,Welcome to visit us !

The SPS from 12 – 14 November 2024 in Nuremberg is the industry highlight of the automation sector and, with its large number of exhibitors and unique concept, represents the complete spectrum of smart and digital automation – from simple sensors to intelligent solutions, from what is feasible today to the vision of a comprehensively digitized industrial world.

CHAIN TAIL HALL 3, STAND 215 , Welcome to visit us !

[ Taiwan Automation Intelligence and Robot Show ]

Venue: Taipei Nangang International Exhibition Center, Hall 2

Address: No. 2, Jingmao 2nd Rd., Nangang District, Taipei City 11568, Taiwan

Automation has developed rapidly and widely range of application recently.

It has become an indispensable valuable addition of industrialization.

This year CT will be attending this show at Hall 2 , No. S1113 , Welcome to visit us!

Mechanical Components & Materials Technology Expo [M-Tech] is an exhibition gathering all kinds of mechanical parts such as bearings, fasteners, mechanical springs, metal and plastic processing technology. M-Tech attracts a significant number of professionals every year from design, development, manufacturing, production engineering, purchasing and quality control departments, to conduct lively business discussions with exhibitors.

This year CT will be attending this show, at HALL ,No. ,Welcome to visit us !

SPS IPC Drives is Europe’s leading exhibition for electric automation.The trade fair offers the perfect platform to present your product range. Convince the trade visitors, a high-qualified audience, that exhibitors offer the right solutions for their automation tasks.

SPS-IPC Drives Nürnberg-Germany will be held from 14 to 16 November 2023

CHAIN TAIL HALL3, STAND 308 , Welcome to visit us !